Hello, this is Shinji from Warashibe-choja.jp. The other day, I went to Nishijin in Kyoto. The aging of craftsmen is advancing, and the number of craftsmen closing their workshops is increasing. I had a meeting with the intention of thinking about something new. Even after I was 70 years old, I was able to talk about a very interesting story with a positive craftsman, so I will summarize it in an article at a later date. This time, I would like to briefly explain about Nishijin-ori.

History of Nishijin-ori

During the Muromachi period, the Onin War (1467-1477), which was a battle that divided Japan into two, ended, and the textile craftsmen who had been scattered around the country returned to Kyoto. Weaving will be resumed around the place where the position of the Western Army led by Yamana Sozen was placed during the war. It is said that it was around this time that the northwestern part of Kyoto, which had prospered as a textile town before the war, came to be called “Nishijin”. In 2022, it will be called Nishijin and it will be the 555th anniversary. It is said that the court has been making textiles in this area since the 5th century. Nishijin’s historic workshops are often certified as historic buildings.

Nishijin-ori

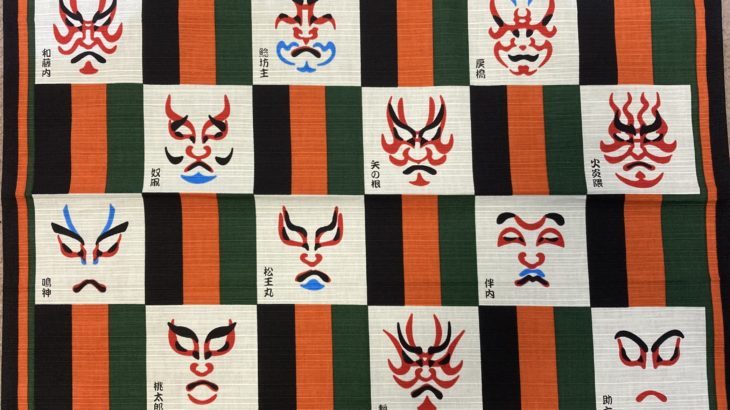

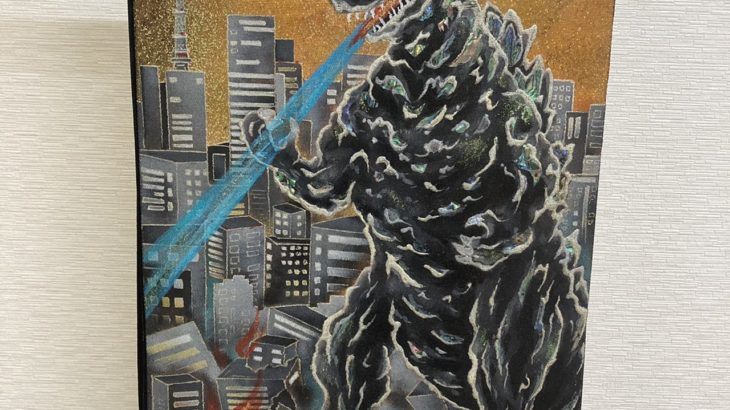

Nishijin-ori is a general term for “yarn-dyed crest fabrics produced in Kyoto (Nishijin), which is characterized by high-mix low-volume production.” It was designated as a national traditional craft on February 26, 1976. Nishijin’s workshop has made various efforts to create excellent designs in addition to the refinement of high technology accumulated since the Heian period.

Nishijin-ori production process

Planning / pattern making process

Zuan (= Design) – Monisyo (= Crest Design Drawing) – Mon-hori (= Crest Carving) – Computer Graphics

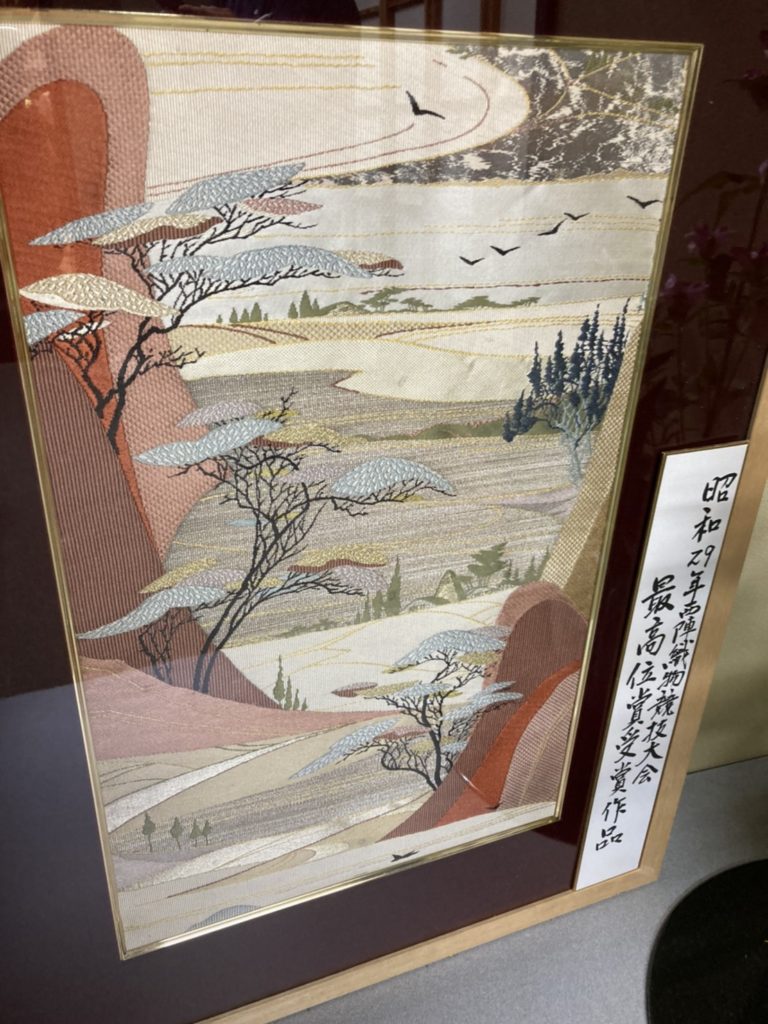

This is the most important process in Nishijin-ori, which is a yarn-dyed crest fabric. I will add a new feeling to the traditional design and draw it. About 50 years ago, there was a craftsman who drew Nishijin-ori designs called design masters, and the designs drawn by those craftsmen were sold for 100,000 to 200,000 yen. This workshop also had about 2000 designs.

Raw material preparation process

Nen-shi (= Twisting the thread) – Ito-zome (= Dyeing the thread) – Ito-kuri (= Rewinding the thread) – Seikei (= Preparing the thread) – Kasuri

There are woven fabrics with various textures in Nishijin-ori, and it is a process to adjust the thickness of the yarn by combining thin yarns and to apply a special twist to the yarn to give it a texture. After that, it is dyed in the color specified by the workshop, wound around the thread frame so that the thread is easy to use, and the required length and number of warp threads are prepared. For Nishijin-ori, use at least 3000 threads. If there are many, 8000 warp threads are used.

Machine preparation process

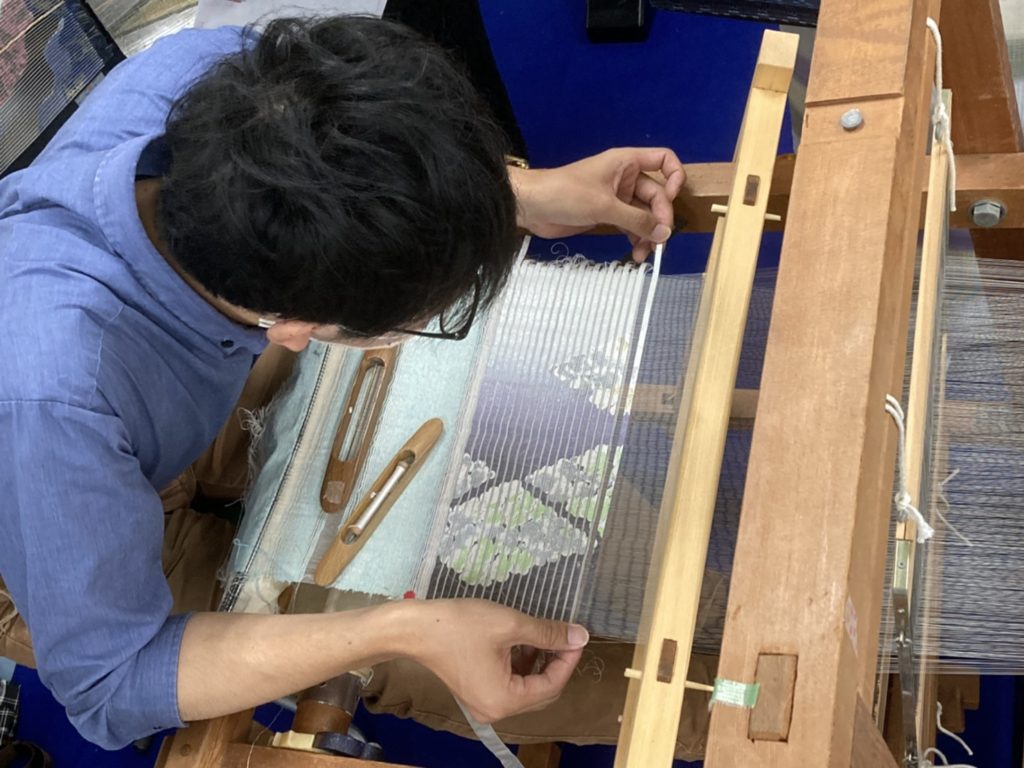

So-ko (= work of threading thread through a machine) -Preparation of jacquard and pattern paper

To weave a woven fabric, the warp must be pulled up to open a Himichi (= space for the shuttle to pass through) through which the weft passes. So-ko is a device that pulls up the warp threads according to Jacquard’s instructions. Until a few decades ago, I used to send the directive on a piece of paper called Mon-gami, but nowadays I often use a computer.

Production process

There are different types of weaving, not the jacquard called “Tsuzure-bata”, but the weaving method that expresses the pattern with a unique scratching of the nails, and the “Te-bata” that uses jacquard but weaves one by one by hand. ], There is a weaving method using a machine called “Riki-syokki”. When weaving Nishijin-ori, the surface is on the bottom, so weave while looking at the pattern using a mirror.

Finishing process

Even in Nishijin weaving, after weaving like Omeshi, it is organized to give a unique texture through steam. Like velvet weaving, there is also velvety processing in which the upper thread is cut after the warp threads are doubled and the warp threads are fluffed.

The Nishijin union issues the Nishijin union number to each obi workshop. The same number will not be issued so that you can tell which workshop weaved by that number. Currently, there are up to the latter half of the 2000s, but there are only a few workshops with three-digit numbers left.

This time, it is an article that you can learn the basics of Nishijin. I am planning to go to Nishijin’s workshop in the fall, so if I find something interesting, I would like to talk about it next time. There is also a place called Nishijin-ori-kaikan where you can experience Nishijin-ori, so if you have a chance, please go there.